In industrial manufacturing, construction, pipelines, shipbuilding, and many other metal fabrication industries, welding forms the foundation of many operations. The quality, strength, and longevity of a weld depend not only on the electrode used but also on the preparation process carried out beforehand. One of the most critical stages of this process is the weld beveling or edge preparation step.

What Is Weld Beveling?

Weld beveling refers to the process of creating an angled edge or groove between two metal parts to be welded together, ensuring a sufficient gap for the filler material. This is typically required for thicker materials (generally over 3–4 mm) to ensure full penetration of the weld through the joint.

In simple welding applications, two thin metal plates can be joined directly without special preparation. However, as material thickness increases, the weld cannot fully penetrate through the entire section. At this point, beveling becomes essential — by shaping the edges into “V”, “X”, or “U” profiles, a groove is formed that allows the weld metal to reach all the way through the joint thickness.

Why Is Weld Beveling So Important?

Poor joint preparation may look solid externally but can hide severe internal defects. In critical applications — such as pressure vessels, steel structures, pipelines, or load-bearing systems — such hidden flaws can lead to catastrophic failures. Below are the main benefits of proper weld beveling:

- Ensures Full Penetration: This is the primary benefit. Beveling allows the weld metal to reach the root of the joint, ensuring complete fusion through the entire material thickness. Incomplete penetration creates the weakest point in the weld and must be avoided.

- Improves Weld Strength: A properly beveled joint distributes the load over a wider area and provides strength comparable to or exceeding that of the base material.

- Reduces Welding Defects: Correct groove geometry minimizes issues such as slag inclusion, lack of fusion, and undercutting by allowing molten metal to flow more freely.

- Facilitates Nondestructive Testing (NDT): Properly prepared joints produce clearer, more interpretable results during radiographic or ultrasonic inspections, making defect detection easier.

- Provides a Cleaner and More Uniform Weld Bead: Welding within a well-prepared groove ensures a more consistent, aesthetic, and sound weld seam.

Common Weld Bevel (Groove) Types

The geometry of a weld groove varies depending on material thickness, welding process, position, and accessibility. The most common types include:

- I-Groove (Square Butt): Used for very thin materials, requires no edge preparation.

- V-Groove: The most commonly used type, suitable for single-sided welding on materials between 3 mm and 20 mm thick.

- X-Groove (Double V): Used for thicker materials. Welding is performed from both sides, requiring less filler metal compared to a single V.

- U-Groove: Preferred for very thick materials. The narrower groove angle requires less filler metal and offers better efficiency, though machining is more complex.

- J-Groove: Commonly used in T-joints or where one side of the part must remain flat.

- Double-U and Double-J Grooves: Variations applied to both sides of very thick materials for improved strength and efficiency.

Illustration: Typical Weld Groove (Bevel) Geometries

Weld Beveling Methods: Mechanical vs. Thermal

Beveling processes can generally be divided into two main categories: Mechanical Methods and Thermal Methods. Each has its own advantages and limitations.

1. Mechanical Beveling Methods

These involve removing material mechanically — by cutting or grinding — without affecting the material structure thermally. Their major advantage is that they do not create a Heat-Affected Zone (HAZ), which means the base metal properties such as hardness and toughness remain intact.

- Milling / Portable Beveling Machines:

- Description: Specialized machines equipped with rotating carbide or HSS cutters that precisely remove material to form smooth, accurately angled bevels. Available as stationary or portable units.

- Advantages:

- Excellent surface finish.

- Precise and adjustable bevel angles.

- No heat distortion.

- Good productivity for consistent results.

- Disadvantages:

- Higher initial investment cost.

- Cutting tools wear over time and require replacement.

- Grinding:

- Description: Uses handheld angle grinders with abrasive discs to manually create bevels; commonly used in workshops and field fabrication.

- Advantages:

- Low cost.

- Can be applied in any position or environment.

- Disadvantages:

- Accuracy depends heavily on operator skill.

- Poor surface finish compared to machining.

- Slow process.

- Generates harmful dust and noise.

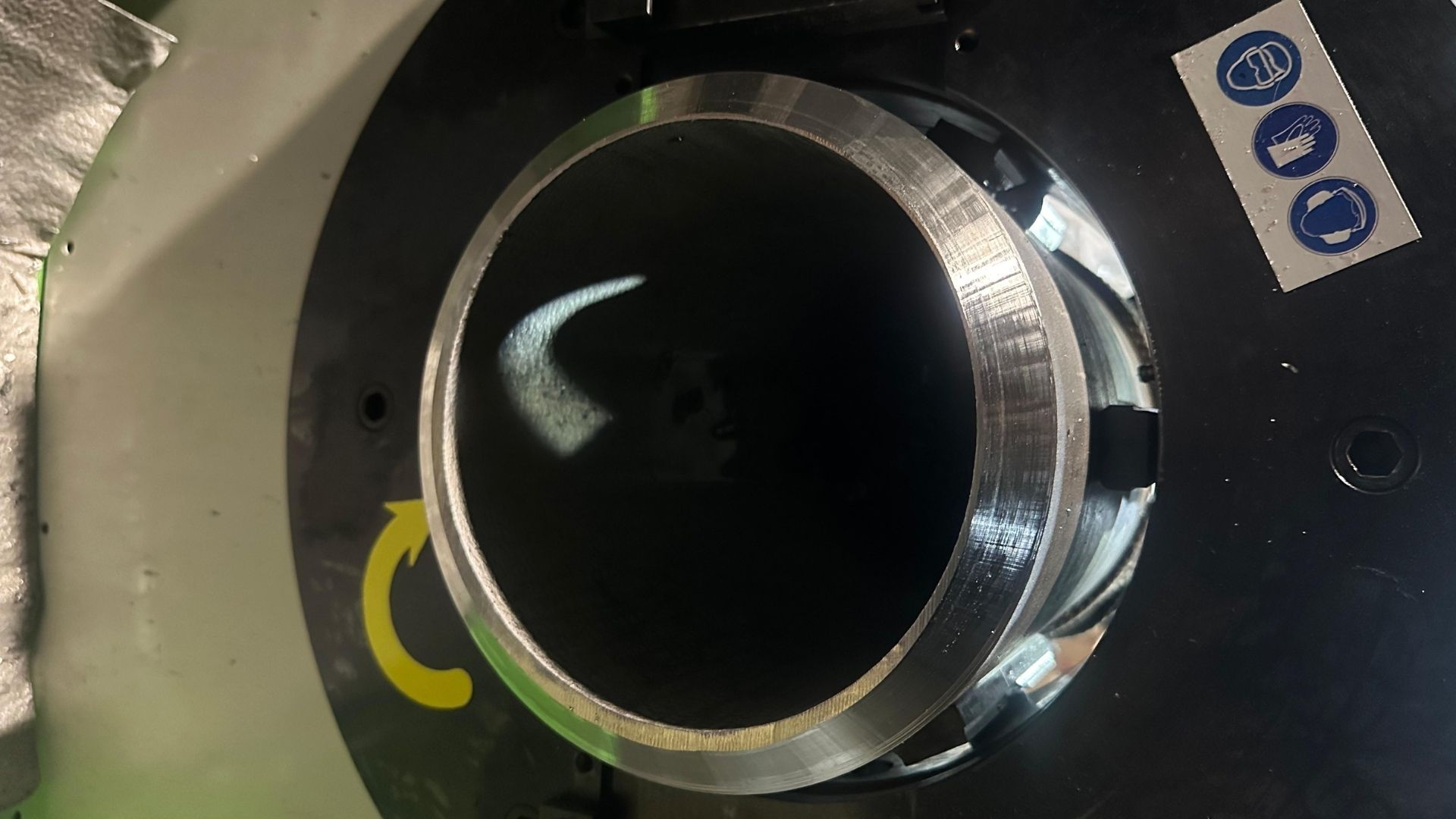

- Turning (Lathe Machining):

- Description: Used mainly for pipes and cylindrical components where precise bevel angles are required on rotary lathes.

- Advantages:

- High precision.

- Ideal for batch or mass production.

- Disadvantages:

- Limited to workshop environments and specific geometries.

2. Thermal Beveling Methods

These use high temperatures to melt or burn the material. They are generally faster than mechanical methods but create a Heat-Affected Zone (HAZ) that can alter material properties.

- Oxy-Acetylene Cutting:

- Description: Uses a flame produced by oxygen and a fuel gas (typically acetylene) to melt or burn metal for cutting or beveling.

- Advantages:

- Effective on thick carbon steels.

- Low investment and suitable for field applications.

- Disadvantages:

- Creates a wide heat-affected zone.

- Rough surface finish requiring post-grinding.

- Not suitable for stainless steel or aluminum.

- Lower precision than mechanical methods.

- Plasma Cutting:

- Description: Uses a high-velocity jet of ionized gas (plasma) to melt and eject metal, forming the desired groove or edge.

- Advantages:

- Much faster than oxy-acetylene cutting.

- Can cut all electrically conductive metals (steel, stainless, aluminum).

- Produces a narrower HAZ and cleaner cut surface.

- Disadvantages:

- Higher equipment cost.

- Slight bevel angle may appear on the cut face.

- Laser Cutting:

- Description: Uses a focused laser beam to precisely melt and cut metal with minimal thermal distortion.

- Advantages:

- Extremely precise and smooth cut surfaces.

- Very narrow HAZ.

- Capable of processing complex shapes.

- Disadvantages:

- High initial investment.

- Reduced efficiency on very thick materials.

Choosing the Right Beveling Method

When selecting the optimal beveling technique, the following factors should be considered:

- Material Type and Thickness: Thermal methods suit carbon steels, while heat-sensitive materials (stainless steels, alloys) should be beveled mechanically.

- Required Quality and Precision: For high-accuracy joints, milling or machining methods are preferred.

- Cost and Productivity: Automated plasma or milling machines are best for production runs, while grinding may suffice for small jobs.

- Application Environment: Portable tools are better suited for on-site work, whereas fixed machines are ideal for workshops.

- Applicable Standards: Codes such as ASME, AWS, or ISO may specify specific preparation or surface quality requirements.

Conclusion: Quality Begins with Preparation

Weld beveling is a critical step in welding preparation. Although often overlooked, it directly determines the safety, durability, and lifespan of the final structure. Poor preparation can lead to problems even the most skilled welder cannot fix.

Selecting the right beveling method for your material, project requirements, and budget ensures not only stronger and safer welds but also prevents costly repairs or failures in the future. A good weld always starts with good preparation.

Frequently Asked Questions (FAQ)

Q1: Is beveling necessary for thin materials? Generally, no. For materials up to around 3–4 mm, simple edge facing is sufficient without beveling.

Q2: What should the bevel angle be? Standard bevel angles range between 30° and 37.5°, but this may vary depending on the project specification or welding code.

Q3: What are the root pass and root gap? The root gap is the intentional space left between two parts after beveling, allowing the weld to penetrate to the bottom. The root pass is the first weld bead deposited in this gap, forming the foundation of the entire weld.

Q4: Why should thermally cut edges be cleaned before welding? Thermal cutting methods such as oxy-fuel or plasma often leave oxide layers and hardened zones (HAZ) on the surface. These can cause porosity or slag inclusion during welding. Therefore, the surface must be ground and cleaned before welding.